The Gilberts were on vacation this week, and what a week it was!

We first drove to St. Louis to see the “Great American Eclipse”. Michigan got roughly 80% of a full eclipse, but we wanted to be in the path of totality. The actual eclipse would happen early afternoon on Monday the 21st, but we wanted to try to miss the massive crowds they were predicting would drive into the St. Louis area, so we left early the morning of Saturday the 19th.

We were all in good spirits on the trip down, and had more than one amusing moment. A couple of our favorites:

- A sign that measured your speed and played it back to you, for example, “Your Speed: 54”. If you were going between 1 and 5 MPH over the limit, it would still show you your speed, but would blink to get your attention. If you were going faster than that, the sign changed to “Your Speed: Slow Down”.

- Mark: “Pinch and zoom is great except when you’re in a car on a bumpy road.”

As usual, CJ planned the drive down to have a couple of stops – the first was a late breakfast at Sophia’s House of Pancakes (which was fantastic). The second one was a mystery – CJ refused to tell us (not even me) where we were going or what we were doing. We drove a little ways off of Route 66 to “Arcadia: America’s Playable Arcade Museum” in McLean, IL – an arcade with a good number of classic video games and pinball machines. We had a couple of rolls of quarters to burn, and the four of us went to town. We spent a lot longer than than we had budgeted (not really a surprise), and CJ and I got to introduce the girls to a lot of the classic games we grew up playing. Lucy ended up getting on the high score board for one of the jet-fighter games, and I even captured the top slot on Galaga!

Once we got into St. Louis, we parked the van, and went to dinner. After that, we walked to the Arch. Besides being in the path of totality, this was the other reason we chose St. Louis – Rick Riordan’s “Percy Jackson” series (which all four of us has read and love) has a very memorable scene at the top of the Arch involving a fire-breathing Chihuahua. To celebrate visiting the scene of said incident, Lucy made sure to wear her Camp Halfblood t-shirt.

The ride up in the “pod” was a little nerve-wracking, but the girls loved the views from the top. We visited in early evening, and Katherine noticed that the arch cast a very long shadow in the setting sun.

The park ranger helping to guide the tourists through saw Lucy’s t-shirt, and asked her to keep an eye out for any Chihuahuas. Lucy smiled, clearly happy that someone got the reference. I told him we figured the “no pets” signs around the arch were put in place precisely for that incident, and he agreed. He then admitted that he was the designed “adult” to a Rick Riordan book signing. When we got back down to ground level, Lucy found two other girls in Camp Halfblood t-shirts, so she got a chance to geek out for a bit. After a visit to the Arch store, we walked back to the van, drove to our hotel, and collapsed.

The next day, Sunday, was mostly spent at the St. Louis Zoo. They have a number of animals that we can’t see at our local zoo, like stingrays:

We actually got to pet the stingrays. They tell you to put your hard flat in the pool, and the rays that want to be petted will swim up to you where you can stroke the tops of their bodies (the zookeepers warn you to not touch their “wings” or their bellies). Lucy didn’t have a very good first impression, unfortunately. One of the first rays that swam up to Lucy bumped into another ray, and a massive splash ensued as the two of them tried to get away. Unfortunately, Lucy was right over them when they tussled, so she got a mouth full of sea water. By the end, though, she got the hang of it, and managed to pet several of the rays, including one of the two “baby” rays that are about the size of a dinner plate, and one of the two “granddaddy” rays that were the size of a coffee table. Katherine and CJ also managed to pet the small shark that was swimming with the rays.

The seal/sea lion aquarium allowed you to walk under the water, and see them swimming by around you and overhead. One of the seals (at least I think it was a seal) got VERY interested in a sippy bottle that one of the other visitors brought.

We don’t know what the animal thought it was seeing from the other side of the glass, but he kept pressing his nose up to the glass trying to get at this very colorful thing, and even let out what looked like a yell underwater, probably voicing its displeasure at not being able to get it.

We also paid a visit to the penguin exhibit.

Because most (but interestingly, not all) of the penguins at the St. Louis Zoo were from much colder climates, they had to keep this building chilly – in the 40s. When we were inside, two of the penguins decided to get into a bit of a snit, and ended up splashing Lucy and CJ. That convinced us to move along.

The next day was eclipse day. Since our hotel was in the path of totality, we decided to hang out in the morning, swim in the indoor/outdoor pool, and generally avoided driving anywhere.

We were SO glad we did because it meant a very relaxing day, and avoiding the congested highways that went on all afternoon and evening. The eclipse was slated to start a little before noon local time, and then reach totality a few seconds before 1:17pm. They were predicting partly cloudy skies, but for the most part we had a beautifully unobstructed view of the sun. We walked to lunch at the Denny’s across the parking lot, and when we got out a little after noon, we took our first peek at the eclipse (using our official eclipse glasses, of course!):

I tried to take a picture through the glasses, and managed to snag this beauty:

We ended up spending the next hour in and out of the pool, and watching the eclipse progress. We could see a definite change to the quality of the light during the 15 minutes or so leading up to totality. Then, a couple of minutes before, the cicadas in the surrounding trees started up. Then totality set in for most of two minutes, and we just admired the eclipse with our naked eyes. I did manage to see the “diamond ring” effect towards the end, but sadly wasn’t able to capture it. I did, however, get a very nice progression:

(click to eclipsify}

The rest of the day was spent in the pool and in our room watching a movie.

The next day, Tuesday, we got up early and left for Chicago. We thanked God again for the awesome weather we had the day before because it was pouring in St. Louis when we left, and rained most of the drive north. We arrived and went to the Field Museum for the afternoon, where the girls proceeded to try to feed me to “Sue” the T-Rex.

The circle of life is complete. When we were last in Chicago 5 years ago, I fed Lucy to Sue.

That evening, we went to our favorite dive in Chicago for dinner – the Weber Grill Restaurant. I introduced Katherine to filet mignon. She admits she isn’t normally a steak person, but after her first bite she smiled and could only manage to say “wow”. 3 minutes later she announced, “and now my steak is gone”. After that fabulous meal, we went back to our hotel, and collapsed.

The next day we spent taking in some of the sights in downtown Chicago. First, the Chicago Cultural Center, former home of the first public library in Chicago:

Then to “bean”, formally known as “Cloud Gate”:

The girls had a lot of fund warping reality:

We then visited a pool where the girls cooled their heels – literally.

And where Lucy nearly got a shower:

None of us realized this initially, but the two giant video-walls that bookend this pool would actually shoot water out periodically.

Apparently, you just wait for the people in the video to smile, and then pucker up. Lucy had been standing right in the blast zone, and just happened to move a few seconds before it went off. If she had gotten doused, we would have had to immediately gone back to the hotel room to change because at 1 o’clock it was time for…

Hamilton! The girls have been listening to the songs for the last year, almost on a permanent repeat, so seeing it on stage was very exciting.

The show was awesome. During the intermission, I found that the family directly behind us also saw the eclipse earlier in the week, so we spent the time between acts geeking out about both that and the show.

After the show, we went to one of Katherine’s favorite places in Chicago (she had come to the Windy City three years in a row for middle school orchestra class trips) – Foodlife, in Water Tower Place.

After that we spent an hour or so shopping, mostly in the LEGO store. After we had been there a while, of the attendants asked me if I was thinking about one of the big sets. “Oh, I’ve been doing a lot of THINKING…” He just smiled and said, “Ah, I know how that goes.”

One of the best parts of the LEGO store (if you haven’t experienced one) is being able to sort through thousands of mini-fig parts (heads, bodies, legs, hats, etc.) to build your own. Normally the component parts are in separate bins, and there is a tray that runs around the kiosk to let you work on your custom creations. I happened to be passing one of the mini-fig stations when one of the attendants was going through the pile of pieces in the tray, sorting them back into their bins. I asked him if this was a daily thing, or if he had to do it more frequently. He just smiled and said they all try to keep up on it, but it’s especially nice during the slow periods. It keeps them active. If Kalamazoo ever opens a LEGO store, I may have just found my retirement job.

Then it was time to head back to hotel for sleep. Given where we were, and where we had to go. Walk 12 blocks – or walk 3 blocks, travel by subway, and then walk another 3. I said we could just walk it. However, on the way out of the mall, the girls noticed that there were horse-drawn carriages lined up like taxis. After a bit of back and forth, we decided to take one. Our driver was Whitney, and our horse was Mr. Festus.

It was a tremendously cool experience. Not only did we not have to walk the 12 blocks, but we got a view of Chicago that I don’t think you can get any other way – slow moving so you can enjoy the sights and architecture, in the middle of the street so you can see both sides well, but you don’t have to be the one paying attention to where you’re going. We asked a lot of questions of Whitney, and she entertained us with stories of horses and her job.

At the end, Whitney explained that while she works for tips, Mr. Festus works for carrots, and she let the girls feed him at the end. The picture above was taken after the girls fed him a couple, and Mr. Festus nuzzled Lucy looking for more.

The next day, we checked out of the hotel, ate at a two-story McDonald’s (a first for all of us; I never imagined McDonald’s needing an escalator!), and then went to the Museum of Science and Industry. The girls are far enough apart in age that they aren’t into the same things, so CJ and I to each take one, which turned out to be a massive stress reliever.

Lucy hit the Idea Factory, and had a blast building towers with an electromagnetic crane:

And playing with the locks (i.e., what you’d find in the Panama Canal or Sault Ste. Marie):

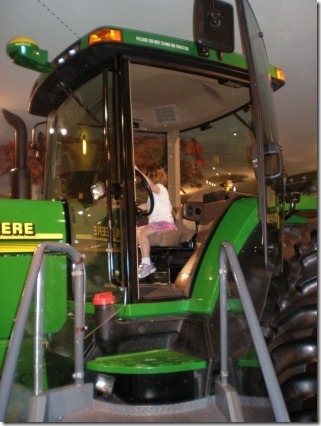

In fact, she tried to corral ALL of the balls into one lock, and according to CJ, nearly overflowed the thing when the water filled in. Lucy also took a turn “driving” the John Deere tractor they have:

The same one, in fact, that she drove 5 years ago when we last visited Chicago ( https://markofquality.wordpress.com/2012/04/02/chicago-vacation-2012/ ):

The chick hatchery is a recurring favorite of ours, and all of us paid a visit at least once.

Lucy and CJ actually managed to see one hatch:

While Katherine and I saw one get flipped over on its back.

Its wings were so short though, it was having a real hard time righting itself.

We had lunch at the museum, spent another 90 minutes or so visiting the exhibits, and then left for home. And it felt SO good to be home.

And so ends a fabulous week of science, art, culture, and fun.